Line for Shimano roller 2BB specification tuning kit [Ver.2]

Our Selling Price: US$19.72 - US$25.41 [Regular Price: US$28.16 - US$36.30]

Prices vary according to options.

[Product concept]

※ selling product is tuning kit, you are not in the reel body.

※ When you select the type of bearing, you will see each of the selling price.

With an emphasis on rotational performance, high sensitivity bearing of

the tournament specifications.

It was adopted strong new material to corrosion, salt water corresponding bearing, which boasts the best of anti-rust and durability performance.

(Bearing of choice)

SHG premium bearing the light lure of freshwater fish and high-sensitivity-oriented, such as trout bus. The all saltwater fish in Salt General is recommended HRCB anti-rust bearings. ※ SHG is also salt can be used but, HRCB if to emphasize the durability is the best.

MAXBB full bearing tuning kit, can be added to BB from commercially available state until the maximum mounting number, "of dedicated bearing dedicated parts such-Manual" is a tuning kit which is full set. Recommended for beginners! We will send to align all the necessary things. ※ simple tool such as a screwdriver or pliers Please prepare.

(Tuning menu)

line roller 2BB specification bearings tune

(contents)

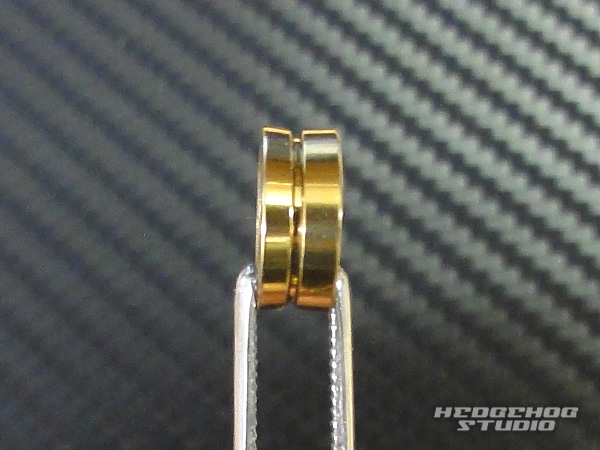

・BB for the line roller (SHG-740ZZ or HRCB-740ZHi)× 2 pieces

・roller bush × 2 pieces

・roller washers A (0.2 mm: thin type)× 3 pieces

・roller washer B (0.8mm: thick type)× 1 pieces

・tuning manual

The line roller of the normal 1BB specification, is the tune to change 2BB specifications, which are used to Stella.

In order to support both sides of the line roller bearings, less blurring of rotation, during the winding of yarn dandruff, etc., even in a state in which no tension is applied to almost line, firmly bearing is rotated, the line roller is to work Kure you.

Bad line roller of the rotation, to prevent the sensitivity of the retrieve, of course, is the cause of the backlash generated useless twist because the maintenance tuning is recommended.

[Compatible models]

・11 TWIN POWER

(1000S,1000PGS,C2000S,C2000HGS,2000S,2500,2500S,C3000,C3000SDH,C3000HG,4000,4000XG)

・13 VANQUISH LIMITED EDITION

(C2000HGS,2500HGS,C3000HGSDH,4000XG)

・12 VANQUISH

(1000S,C2000S,C2000HGS,2000S,C2500HGS,2500S,2500HGS,C3000,C3000HG,C3000SDH,4000,4000XG)

・13-14-15 AR-C AERO CI4+

(C3000HG,4000,4000XG,5000XG)

・14-15 AR-C AERO BB

(C3000HG,4000,4000HG,5000HG)

・13 SOARE CI4+

(C2000PGSS,2000HGS)

・13 SOARE BB

(C2000PGSS,2000HGS)

・15 EXSENCE LB

(C2000MDH)

・14 EXSENCE BB

(C3000M, C3000HGM, 4000HGM)

・12 EXSENCE CI4+

(C3000M,C3000HGM,4000S,4000XGS)

・11 EXSENCE BB

(C3000M,C3000HGM,4000S,4000HGS)

・15 SEPHIA SS

(C3000S,C3000HGS,C3000SDH,C3000HGSDH)

・13 SEPHIA BB

(C3000S,C3000HGS,C3000SDH,C3000HGSDH)

・12 SEPHIA CI4+

(C3000S,C3000HGS,C3000SDH,C3000HGSDH)

・12 CARDIFF CI4+

(C2000SS,C2000HGS)

・12 ULTEGRA

(1000,1000S,C2000S,C2000HGS,2500,2500S,C3000HG,C3000SDH,4000HG)

・13 COMPLEX CI4+

(2500S F4 ,2500S F6 ,2500HGS F4 ,2500HGS F6)

・12 COMPLEX BB

(2500HGS F4 ,2500HGS F6 ,2500S F4 ,2500S F6 )

・12 Reaniumu CI4+

(1000S,C2000S,C2000HGS,2500,2500S,C3000,C3000HG,4000XG)

・13 NASCI

(1000S,C2000,C2000HGS,2500,2500S,C3000,C3000HG,C3000SDH,4000HG,C5000)

・13 BIOMASTER SW

(4000XG,4000HG,5000XG,5000PG)

※8000HG,8000PG,10000HGにはご使用できません。

・11 BIOMASTER

(1000S,C2000S,C2000HGS,2000S,2500,2500S,C3000,C3000SDH,C3000HG,4000,4000HG,C5000)

※6000,8000にはご使用できません。

・10 BIOMASTER SW

(4000PG,4000XG)

※6000HG,6000PG,8000HG,8000PGにはご使用できません。

・14BB-X Hyper Force

(1700DHG, 1700DXG, C2000DHG, C2000DXG)

・15BB-X RINKAI Special

(1700DXG)

[Mounting method]

describes the 15 Sefia SS to the base.

We will continue to decompose the line roller.

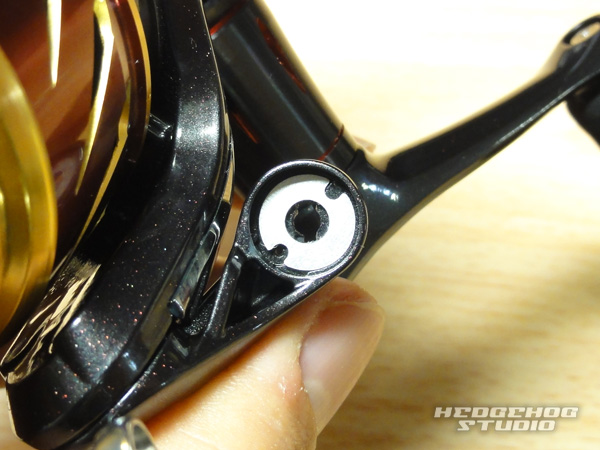

Remove the screws that secure the line roller portion.

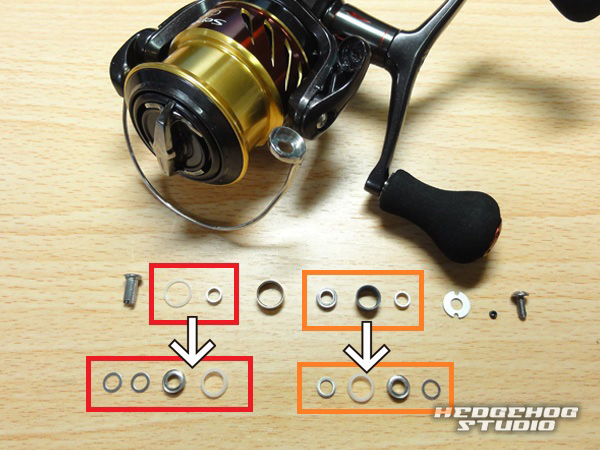

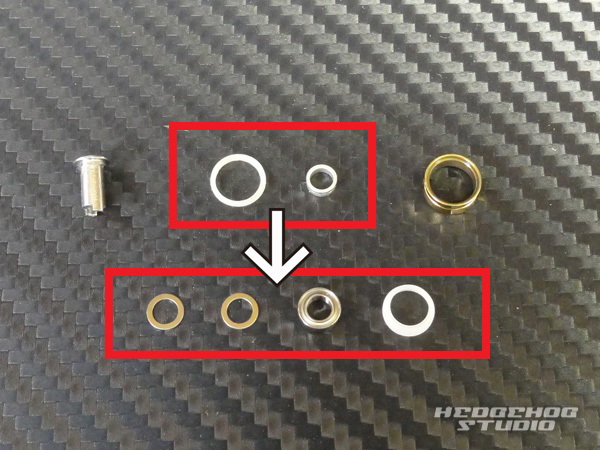

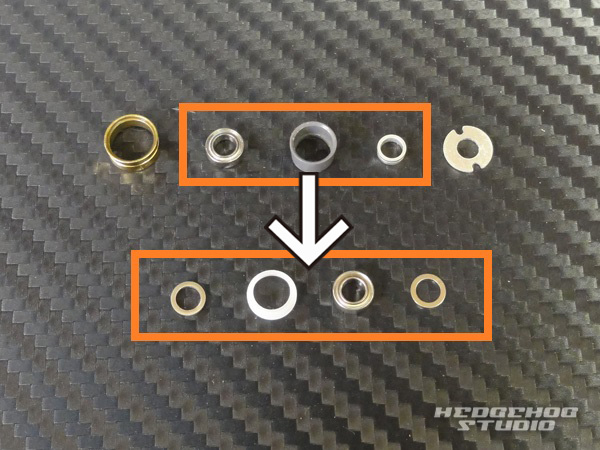

Genuine parts that are arranged in the top row. Of these, each surrounded by parts we are reclassified parts that came with the 2BB tuning kit.

There is a strict orientation to the line roller. Please keep in check

the original orientation when removing. More wide width will be the head

side of the screw many.

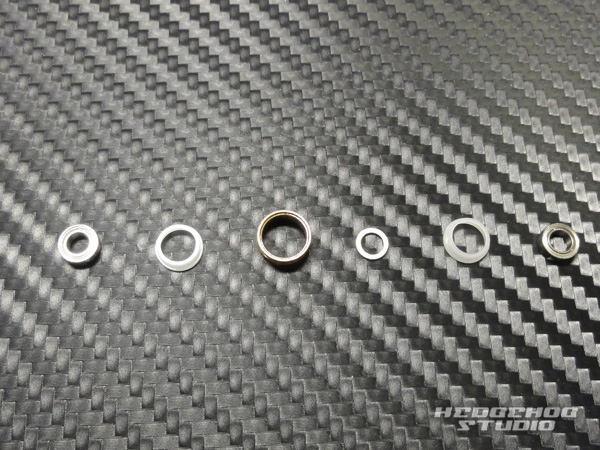

On the left side of the line roller, roller washers A of accessory parts

(0.2mm: thin type) × 2, bearing × 1, and using a roller bush × 1.

On the right side of the line roller, roller washers B of accessory parts (0.8mm: thick type) × 1, Laura Bush × 1, bearing × 1, roller washer A (0.2mm: thin type) × 1, received line roller (genuine you used the parts.

so, we will incorporate parts. first, install the rubber ring of genuine

parts in the arm cam. since it is a very small parts, please be careful

not to lose even when the assembly is also the time of decomposition.

then genuine parts Include the line roller received. This parts, please

pay attention to mating.

post and advance mounted bearings in the line roller will is likely to be. attaching parts from the left side, bearing roller Bush line roller body roller washer B: of (0.8mm thick type) roller Bush bearings . It will be in order

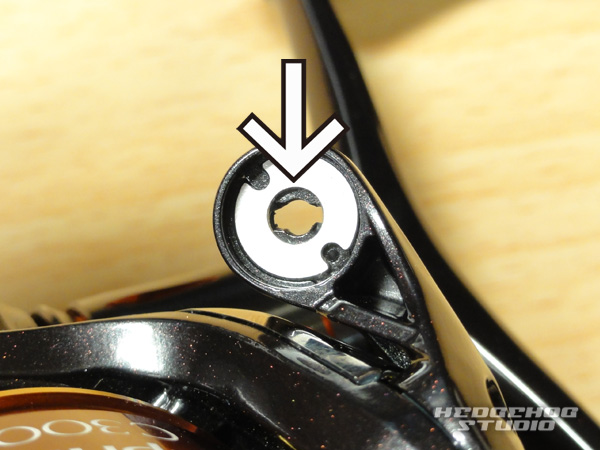

to attach the arm fixed shaft to the arm portion so also there is a matching

fit this part Please note..

Followed by roller washer A.: You install two (0.2mm thin type)

earlier assembly line roller Attach the body. Please pay attention to the orientation of the line roller.

Roller washer A: Install one of the (0.2m thin type).

Built-in part in so far is the end. The following returns on the basis

of the arm cam. In this case, and that there is a visual alignment is in

parts, that it may arm cam back vigorously by the force of the spring,

please go back slowly while always pressing with a finger.

Finally, tighten the screws, is the work completed if the rotation without problems by turning the line roller.

Baitcasting Reel

Baitcasting Reel

![Photo1: Line for Shimano roller 2BB specification tuning kit [Ver.2]](https://www.hedgehog-studio.co.jp/data/hedgehog-studio/_/70726f647563742f32303139313130355f3332333532312e6a7067003330300000660066.jpg)