[LIVRE] BJ 75-83 Handle *LIVHASH

[LIVRE] BJ 75-83 Handle *LIVHASH

Our Selling Price: US$169.40+ [Regular Price: US$242.00]

Prices vary according to options.

* Please note that it takes about 4 to 5 days for us to get ready to send LIVRE handles since it's back-ordered after receiving your order.

|

|||||||||||||||||||||

| Model | Manufacturer Type | Center Nut | Pitch (mm) | Weight (g) | Product No. | Item No. |

| BJ 75-83 | DAIWA/SHIMANO M8 | Right | 75-83 | 62.5 | BJ-78SDR | 621* |

| Left | 62.5 | BJ-78SDL | 622* | |||

| SHIMANO M7 | RIGHT | 62.2 | BJ-78M7R | 624* | ||

| Left | 62.2 | BJ-78M7L | 625* | |||

| DAIWA B1 | 63.2 | BJ-78DRY | 623* | |||

| DAIWA B2 | 63.2 | BJ-78DB2 | 626* | |||

| Main Plate | Titanium Knob | Center Nut | Aluminum Knob Collar | Item No. |

| Gunmetal | Fire | Gold | Gold | 1 |

| Gunmetal | Titanium | Titanium | 2 | |

| Titanium | Gold | Gold | 4 | |

| Titanium | Red | Red | 6 | |

| Gunmetal | Red | Red | 7 | |

| Gunmetal | Blue | Blue | 8 | |

| Titanium | Blue | Blue | 9 |

Product Description

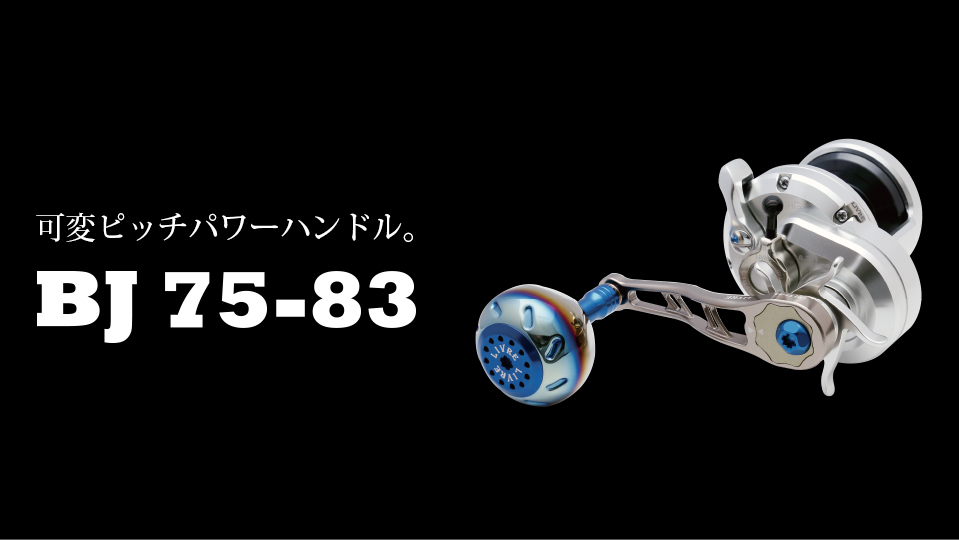

Variable Pitch Power Handle

BJ 75-83

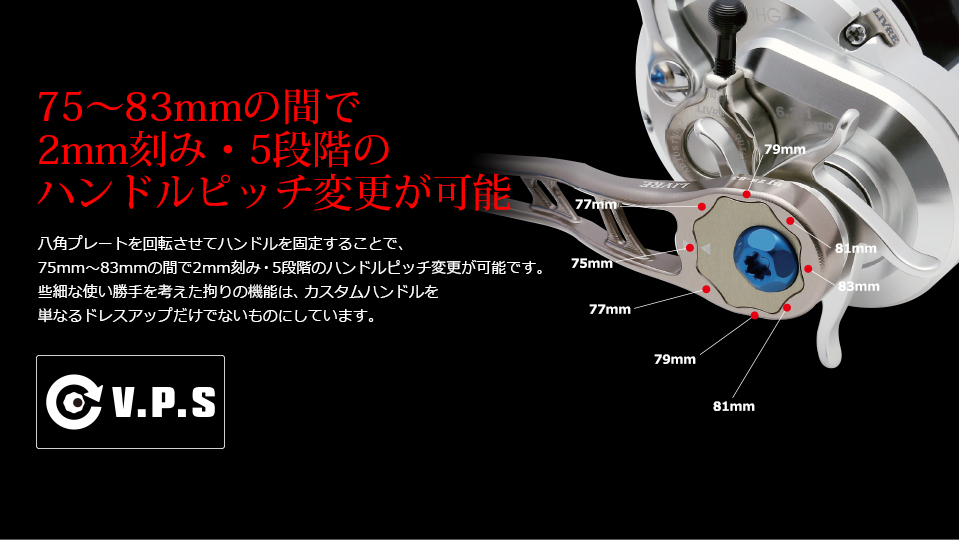

Adjustable Handle Pitch in 2mm Increments, 5 Steps within the Range of 75mm to 83mm

By rotating the octagonal plate to fix the handle, you can adjust the handle pitch in 2mm increments across 5 steps within the 75mm to 83mm range.

These meticulous usability considerations and dedicated functions make this custom handle more than just a dress-up accessory.

Equipped with Ultra-lightweight Thin-walled Hollow Titanium Knob “EP 44”

The palm side features a round shape with dimple processing, while the reel side has a gentle pentagon shape.

This design ensures a gentle feel for the palm and a non-slip grip for the fingers.

The EP 44 has a diameter of 44mm.

Titanium is used as the material, balancing rigidity and weight. The thin-walled hollow structure is welded from the top and bottom parts.

The craftsmen add a burnt color by hand.

A7075 Super Duralumin 3D Machining

Super duralumin is a type of aluminum alloy known as “A7075” in Japanese Industrial Standards (JIS).

It is renowned for its excellent stress resistance and is used in thick plates and forgings.

This material is precision machined into an H-section 3D cut. Prioritizing high rigidity, this machining process achieves the maximum weight reduction.

Baitcasting Reel

Baitcasting Reel

![Photo1: [LIVRE] BJ 75-83 Handle *LIVHASH](https://www.hedgehog-studio.co.jp/data/hedgehog-studio/_/70726f647563742f32303135313030365f6136646339642e6a7067003330300000660066.jpg)