[IOS Factory] D-System Drag Upgrade Kit for DAIWA *SDSY

Our Selling Price: US$30.80 [Regular Price: US$44.00]

The IOS D-system is a drag unit and custom parts that make the drag of Daiwa reels smoother and enable more effective hooking.

The aluminum machine-cut housing provides high-precision spool rotation,

and the concept of the spool being supported by a high-precision bearing instead of a resin collar, which has unstable surface pressure,

is a key factor in the stability of drag action.

The concept of the spool being supported by a high-precision bearing instead of a plastic collar with unstable contact pressure,

combined with the synergistic effect of the special felt developed for the D-System, enhances the stability of the drag action.

The drag spring has also been refined and fine-tuned to have a pleasant tone without impairing drag performance, and an adjustment shim is included to prevent uneven taper winding of the spool, making it compatible with a variety of reels.

■Included thing

DSystem main unit, special stainless steel bearing, special drag spring, special felt

Various adjustment shims, dedicated fixing rings, installation instructions (described in the package)

※Being careful

・Please be sure to install the correct one for your reel when you purchase it.

・If the size does not match, not only will the product not perform well, but in the worst case, it may not be able to be installed.

※When removing the stock drag unit of 15 Iguisto or 15 Rubias and installing the D-system, a special tool such as the "IOS Multi-tool" is required to disassemble the stock drag unit.

Please purchase separately.

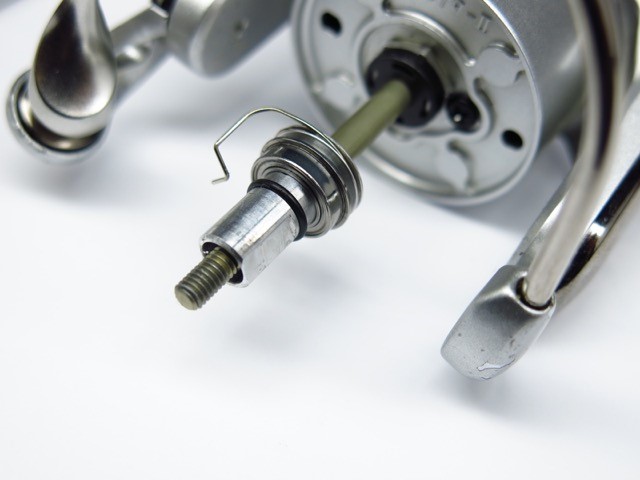

TD series Installation example

Real Four system Fitting example

◎D-System Installation Method for Real

1 Remove the spool from the reel, remove the existing drag felt, apply IOS Shirokuma drag grease generously on both sides to the D-system supplied felt, and reassemble the spool.

Shirokuma grease is characterized by its firm tameness, but if smoothness is a priority, use genuine drag grease.

For the 2500 class, please use the new genuine felt.

2 Remove the main shaft ring, remove the ball bearing, and then pull out the shaft pin. (The pin will be diverted later.)

3 Pull the spool receptor from the main shaft.

4 Install the IOS-D system unit on the main shaft with the finesse-compatible drag spring installed in advance.

The spring can be installed with the spring supplied with the D-system or an existing spring can be diverted. (Adjustment required)

※Increasing the spring rate to make the sound louder may accelerate wear of the spline on the back side of the spool.

When assembling the spring to the main body of the D system, oil is added to the spring to make the sound clearer.

※ Important **** About spool wear *****

For the D system, if the spline where the drag contacts the back side of the spool is worn out, please divert the stock spring and install it.

If the spring supplied with the D-system is installed on a spool that has a lot of wear, the grooves may be easily dug and partial wear may develop.

In addition, using a reel with a higher spring rate, for example, by increasing the drag sound, may also cause premature wear and may not produce the original drag performance, just as with a stock reel.

Please use a spool that is not worn as much as possible and use a low drag noise.

5 先Insert the shaft pin that was removed earlier.

6 Set the 1mm washer supplied with the body of the D system.

(Caution: Washers may need to be adjusted depending on how the line is wound up.)

7 After attaching the supplied bearings with care and direction, attach the 0 ring to prevent them from falling out.

※Note the orientation of the bearing flange!

8 Fit the spool and conduct a drag sound operation check.

The spring included is a finesse spring, but an existing spring can also be installed. (Adjustment required)

★Removal procedure for ATD drag unit installed on Daiwa 15 Iggisto, 15 Rubias and later.

Even difficult ATDs can be easily removed with the IOS multi-tool.

■It can be detached by the following procedure

1 Remove the ATD drag washer from the 15EXIST.

2 Using the IOS multi-tool, turn counterclockwise to loosen the nut.

3 Make sure the nut is completely removed and gently push the pin out with the tip of the multi-tool.

The pin stops loosely and requires no force.

4 Pull out the ATD unit to complete the process.

After removing it, insert the base of the D system and fix it with pins.

The factory fixing nuts are not required.

The factory fixing nuts are not required.

The rest is the same as the installation of the 12 Iggisto.

Refer to the installation instructions.

*************** If no sound is heard *******************

Please refer to the following figure to check the operation of the unit by removing it once and checking the operation of the unit alone as shown below.

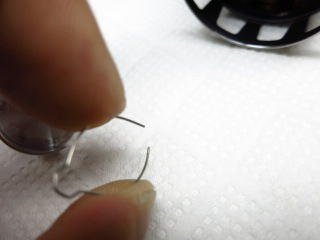

■Case 1

Cases where the spring is sticking out of the spool and will not fit.

As shown in the figure below, the ba-ne protrudes from the spline of the spool, so it does not fit into the spool correctly and no sound is produced.

Support: The amount of sound protruding from the unit can be kept low, and at the same time, the intensity of the sound can be adjusted.

Re-bend the spring width narrower as shown below.

The amount of pop-out is adjusted by bending the spring.

Example of spring properly seated on spool

■Case 2

Cases in which the sound quality of the spring is poor or there is a sticking feeling due to the use of stock springs, etc.

The end of the stock spring may be in contact with the back side of the spool, so please cut 1 to 2 mm off the end as shown below.

■Case 3

Everything is installed correctly, but no sound.

It is possible that the spring is not reaching the spline of the spool.

Either widen the spring slightly to increase the amount of pop-out, or gently bend the convex part of the spring upward at an angle so that it hits the spline.

Especially in cases where washers are increased by 1.5 mm or more, the above measures are necessary.

Adjustment of pop-out amount by spring bending

Spring is not reaching the spline.

Bend the tip of the spring upward

Example of a spring bent to fit tightly into a spline.

■Case 4

Poor drag sound.

The spring that comes with the D system is basically set to produce the best sound with the Iggisto 2004 spool, but the sound quality may be poor if the spline where the drag contacts the back side of the spool is worn out.

In this case, please readjust the spring or try to use the stock spring.

■Case 5

12EXIST Series Edition

When the 12EXIST stock spring is incorporated, it may not make contact with the splines and may not sound.

The reason for this is that the spring does not fit inside the unit sufficiently to allow the spring to pop out.

v

Example of 12EXIST series with stock spring and no spring

Narrow the spring width slightly with your fingers.

The spring adheres tightly to the inside of the unit, and the amount of spring ejection increases to produce sound.

※The spool and drag knob turn together or contact the drag knob when the bail is raised.

Depending on the reel model and individual variability, the spool may not fit tightly into the drag unit, and when the drag knob is tightened, the drag knob may turn simultaneously with the spool rotation.

Please mount the spool firmly as shown below, or if the surface to be mounted is too tight, use the genuine drag felt with a thinner felt thickness instead of the felt supplied with the D-system.

Example of spool not properly attached to D-system

Example of spool correctly attached to D-system

■Line wind-up test

Uneven winding (forward taper, reverse taper) can be adjusted by increasing or decreasing the washers (0.5 mm, 1.0 mm, 2.0 mm) provided.

Basic base is 1.0mm

■Operation check

After the line is threaded through the rod, an actual drag operation test is conducted.

If the drag noise is too loud or the drag grease is too low, the spool will not rotate smoothly,

so reducing the spring tension or additionally soaking the drag felt with plenty of Shirokuma grease will result in stable and smooth drag control while leaving a firm tame drag.

For even greater smoothness, use genuine drag grease.

Also, if the spool center is collared, the performance of the D-system cannot be 100% demonstrated, so it is necessary to incorporate bearings into the spool center, so please feel free to contact us.

■A curling sound is heard from the drag.

〈Case〉

Water ingress in the drag.

〈Solution〉

Overfall in the drag.

Apply more Shirokuma grease.

〈Case〉

Drag knob is too tight and drag grease is not adhering to the felt.

〈Solution〉

Overfall in the drag.

Use 1-3 lb of line, which is normally assumed to be used.

When using more than 3lb, please use genuine felt.

■Daily maintenance

The D system is not effective unless the drag felt and drag grease are kept in good condition at all times.

The special felt is always coated with more IOS drag grease.

D Apply IOS-02 to the system body bearings as needed.

Daily maintenance is performed every few fishing trips.

It is recommended to do this every time, especially after a rainy day or before and after a tournament.

※The special felt is a consumable item.

Replace them every few months.

We will be happy to purchase them for $5.50 for a pack of 3.

◎For D-system and TD Installation method

1 Remove the spool from the reel body.

2 Remove the O-ring and bearing, then remove the shaft pin.

3 Assemble the D system unit.

4 Install the shaft pin.

5 Install 1mm washer. (Usually, 1 mm washers must be adjusted depending on the individual unit.)

6 Assemble the bearings, paying attention to their orientation.

7 O-ring assembly is completed.

8 Spool Washers are coated with Shirokuma grease for overhaul.

9 Assembled as before disassembled

10 Assemble the reel body, paying attention to the cutouts.

11 Unevenness adjustment of the line winding is carried out; the unevenness adjustment is adjusted with the washers provided.

■on installation

Installation is not as difficult as the REAL FOUR D system,

but it does require some skill in overhauling the drag and adjusting the unevenness of the line winding.

Overhaul is performed by recommending Shirokuma drag grease and adjusting line winding irregularities by increasing or decreasing the number of special washers.

To maintain drag performance, a drag overhaul should be performed once every few fishing trips.

If the drag is caught on the curculature, the spool should also be overhauled.

Use the supplied special drag spring.

Baitcasting Reel

Baitcasting Reel

![Photo1: [IOS Factory] D-System Drag Upgrade Kit for DAIWA *SDSY](https://www.hedgehog-studio.co.jp/data/hedgehog-studio/_/70726f647563742f32303139303230385f6666376535362e6a7067003330300000660066.jpg)

![Photo2: [IOS Factory] D-System Drag Upgrade Kit for DAIWA *SDSY](https://www.hedgehog-studio.co.jp/data/hedgehog-studio/_/70726f647563742f32303139303230385f3030653938322e6a7067003330300000660066.jpg)

![Photo3: [IOS Factory] D-System Drag Upgrade Kit for DAIWA *SDSY](https://www.hedgehog-studio.co.jp/data/hedgehog-studio/_/70726f647563742f32303139303230385f3132333037362e6a7067003330300000660066.jpg)

![[IOS Factory] D-System Felt Washer *SDSY](https://www.hedgehog-studio.co.jp/data/hedgehog-studio/_/70726f647563742f32303137303231365f3730613364642e6a7067003230300000660066.jpg)