[IOS Factory] D-system Drag Upgrade Kit for DAIWA 2018 year models [Paraiba Blue] *SDSY

Our Selling Price: US$38.50 [Regular Price: US$55.00]

Item Description

Feature

High-strength, ultra-lightweight system with machine-cut one-piece housing

Stable and sensitive control from only 1LB class to drag breaking strength

Popular Paraiba blue anodized aluminum specification for salt use

Completely original custom parts with a sense of high precision, even a single fixing screw is a matter of concern.

This is a new drag system created for the LT concept.

Product Name

IOS D-system for 18 series Salt Complete Compatible Product

Contents

D-system main body (high-strength A7075 super duralumin + corrosion-resistant alumite treatment)

Exclusive stainless steel bearing, stainless steel drag spring (included), adjusting shim

Dedicated stainless steel fixing screw (5 mm) Please use genuine pins depending on the reel model.

Dedicated screwdriver, installation manual (also used as mounting paper), 1 piece of dedicated felt for 2000 class

* To improve 100% drag performance, we recommend applying Sirokuma Drag Grease to the drag washers and installing Line Roller Direct.

Example of Installation Method

18 EXIST 1000-3000 class

19 TATULA Spinning 2000, 2500 class

First, mark the edges of the existing spool and rotor and fix them so that they do not move until the end of the spool.

1 Remove the existing drag unit with the special screwdriver provided.

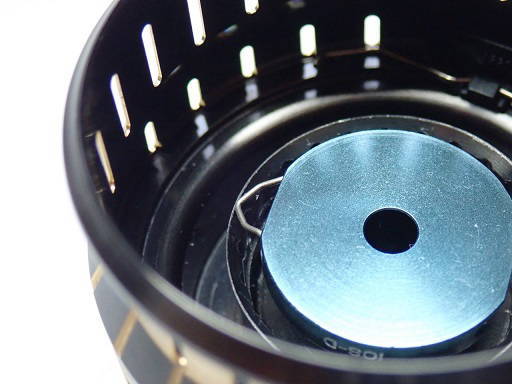

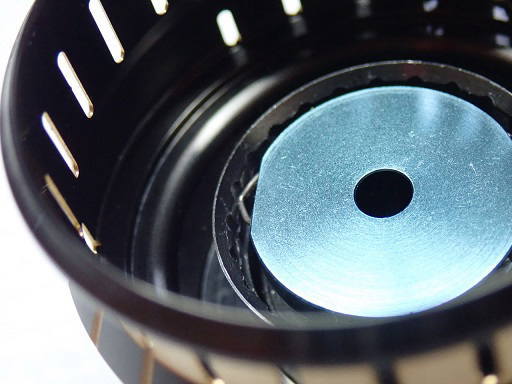

2 Attach the D-system to the main shaft and lightly fasten with the included special screws (be careful not to overtighten).

Commercial tools are used for the purpose of photography.

3 Attach adjustment shims to the D-system.

18 EXIST is standard with 0.5 mm shims and TATULA is standard with 1.0 mm shims.

4 Once the shims are installed (sometimes without), set the bearings and 0-rings, and you are done.

5 Finally, check if the drag spring is making a sound, and adjust the strength of the sound by expanding or contracting the spring.

Check for uneven winding of the line and adjust the shim thickness.

If the line winding is reverse taper, add shims; if the line winding is forward taper, reduce shims.

Incidentally, due to the uneven winding of the line, the shim can be operated without shimming.

To improve drag performance by 100%, we recommend applying Sirokuma Drag Grease to the drag washers and installing Line Roller Direct.

********* How to adjust the D-system if it doesn't spool, doesn't ring, or is quiet *********

As is common with all D-systems, depending on the reel model, the D-system may not enter the spool, the drag sound may be faint, or the sound may be low.

By adjusting the spring, it is possible to get closer to the desired sound.

Symptoms

D-system cannot be set on spool, sound is faint and small.

Correspondence 1 (Elementary)

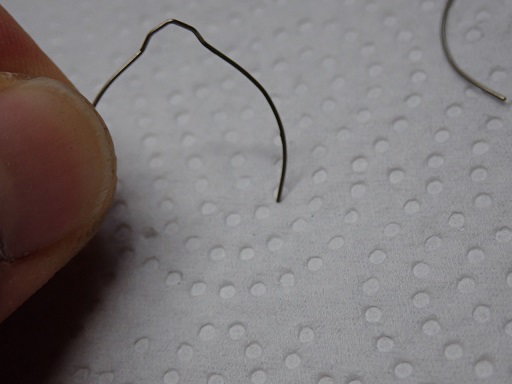

Adjust the angle of the upper sharp corner of the drag spring by lightly crushing it flat with pliers or the like.

The more acute the angle, the higher the sound, and the closer to flat, the lower the sound.

Adjust within a slight angle range.

The upper spring is after adjustment and the lower spring is in stock condition before adjustment.

Symptoms

D-system cannot be set on spool, sound is faint and small

Correspondence 2 (Intermediate)

Further widen the opening at the end of the drag spring.

The wider it is, the louder and fainter the sound becomes.

Left is the open state after adjustment, right is the stock state

Symptoms

D-system cannot be set on spool, sound is faint and small.

Correspondence 3 (Advanced)

If the above does not work, build the D-system into the spool by itself, adjust the inclination of the drag spring, and repeat the corresponding adjustments 1 through 3 while checking the operation.

Spring has popped out and will not fit inside.

Bend upward gently with pliers, etc.

It creates a gap between the spring and the inside of the spring and makes it easier to get inside.

Repeat the adjustment of correspondence 1 to 3 while checking the operation.

![Photo1: [IOS Factory] D-system Drag Upgrade Kit for DAIWA 2018 year models [Paraiba Blue] *SDSY (1)](https://www.hedgehog-studio.co.jp/phone/data/hedgehog-studio/_/70726f647563742f32303139313031375f3164356263642e6a70670036303000534f4c44204f55540074006669745f686569676874.jpg)